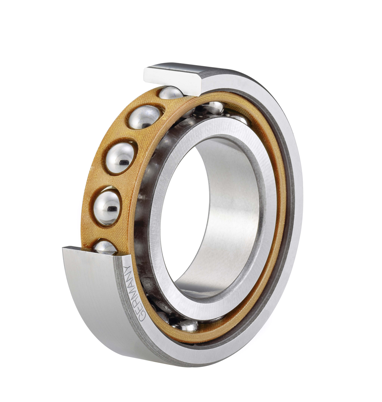

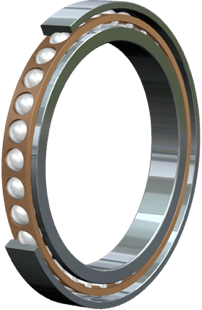

Ball Bearing - Spherical Roller Bearings

About

Spherical roller bearings are characterized by their low-friction rotation. They are renowned for their angular misalignment, caused as a result of heavy loads that cause a shaft deflection between the spherical internal mechanism and the spherical rollers placed on the outer rings. However, these ball bearings have self-aligning capabilities, due to the engineered curving of the external ring raceways in relation to the bearing axis. These devices are shock resistant, carry particularly high radial and axial loads and accommodate to heavy vibrations and polluted environments, while functioning with extra precision on the bore.

Engineering & Design

Spherical roller bearings are designed with two rows of rollers, an external spherical raceway ring and two internal raceways angled to accommodate to the rotating shaft. The barrel-shaped rollers are thus located between the two internal raceways, and a sealed or unsealed cage can be applied.

The construction of the rollers, raceways and cages, as well as the heat treatment and the external finishing are the prime factors that influence the device's performance. For example, symmetrical rollers optimize the load distribution, maximizing the ball bearing's lifespan.

While various aspects of the mechanism are ISO regulated, some internal characteristics of the device are not. As a result, in order to classify as a spherical roller bearing, the manufacturer can alter the mechanism's lubrication method, presence of a central flange, implementation of a central ring and application of a supporting cage. Spherical roller bearings are typically produced with straight bores, but tapered bores are sometimes available if required by the consumer.

Models

Spherical roller bearings may come as single-row spherical roller bearings (sometimes referred to as barrel bearings) which are more suitable for smaller radial loads, or double-row spherical roller bearings, which are equipped with central flanges, optimizing the mechanism's performance.

Chrome steel is the most commonly used material for spherical roller bearings, but sheet steel, regular steel, polyamide and brass are also widely utilized. Likewise, the cages are available in machined or pressed steel, sheet metal, polyamide or machined brass. The cage's strength increases in correlation with the resistance to temperature.

Spherical roller bearings are available in multiple standardized ISO dimensions, which are defined by the size of the apparatus's external measurements.

Applications

Spherical roller bearings are primarily used in heavily industrial settings. Some examples of usages for these spherical ball bearings include, but are not limited to: gearboxes, wind turbines, continuous casting machines, mechanical fans, mining and construction equipment, paper processing equipment, offshore drilling, marine propulsion and agricultural machinery.

Haven't found what you want? Look here